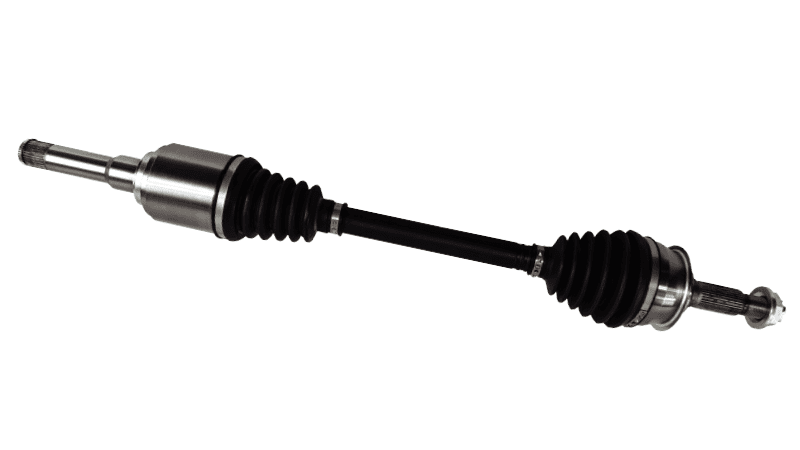

Automotive CV Axles

Black Line™ Premium CV Axles

ESTABLISHING THE NEW STANDARD

New Premium CV Axles

AUTO & LIGHT DUTY TRUCK

EV CV Axles

ELECTRIC VEHICLES

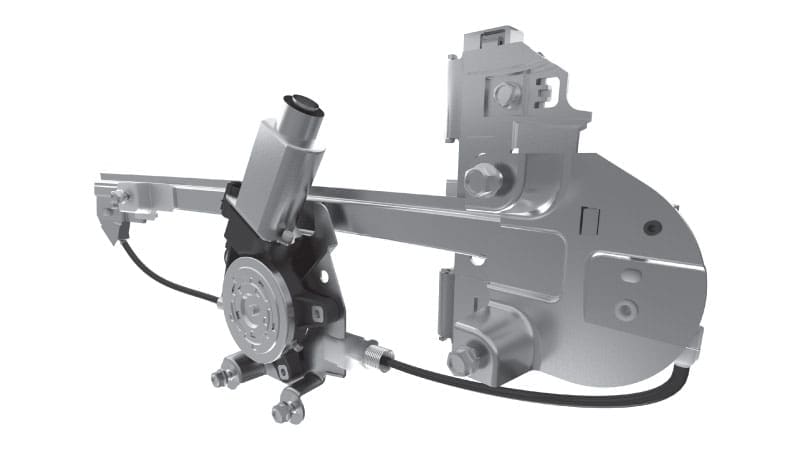

Other Product Lines

Learn on the Go with our Podcast Series

Delivering Premium Performance by Exceeding OEM Fit, Form & Function

TrakMotive parts are manufactured in our state-of-the-art ISO 9001:2015 and IATF 16949.2016 facility and engineered to the highest quality standards in the industry.

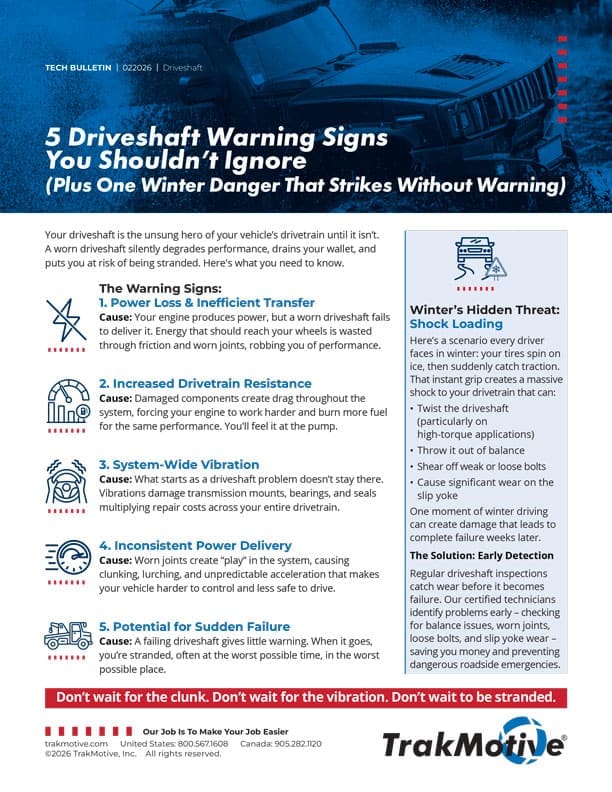

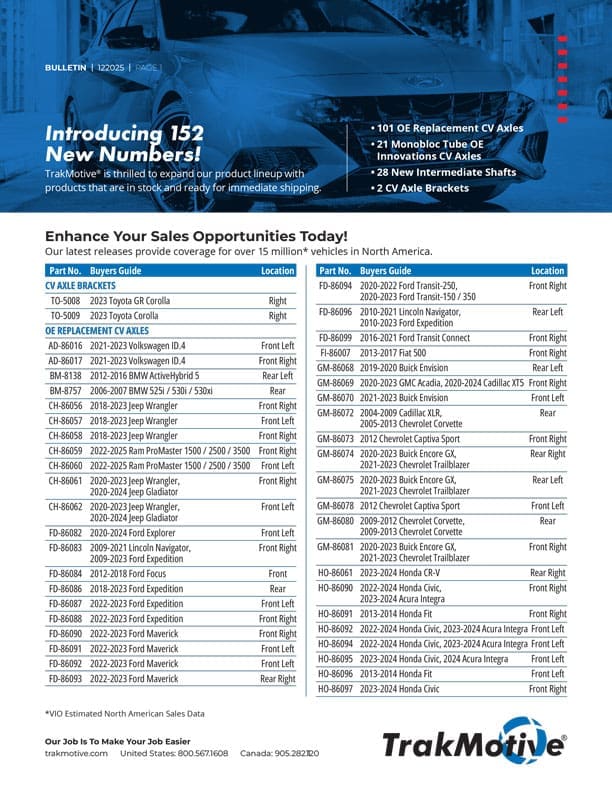

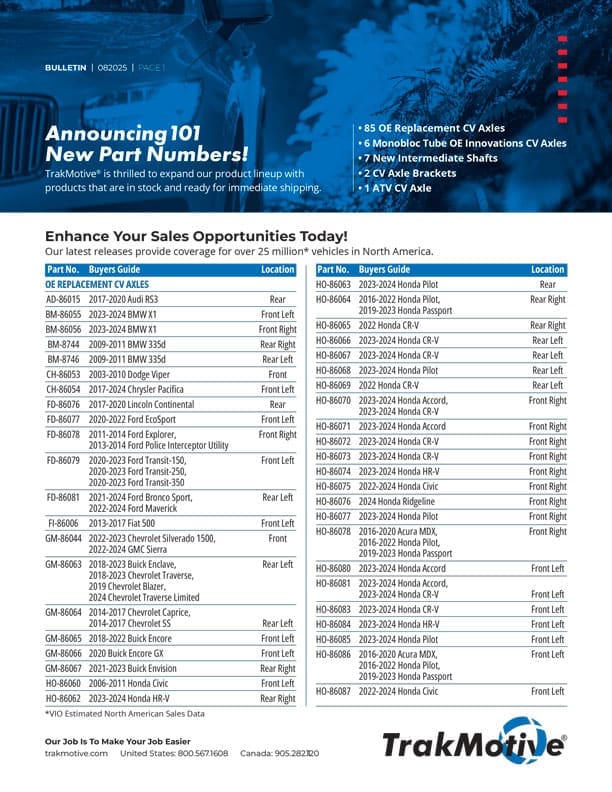

News, Updates & Tech Tips

Never Miss an Update!

Subscribe, follow & like to stay up-to-date with all of the most recent news & updates.