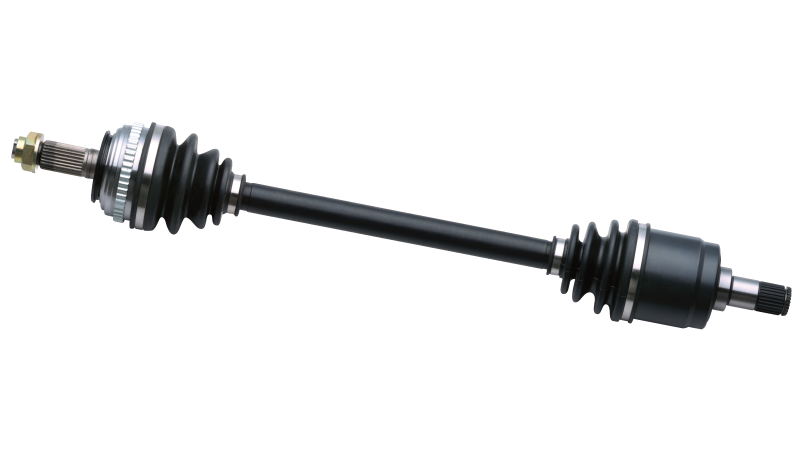

New Premium CV Axles

Leading CV Axle Replacement Program

Automotive & Light Duty Truck

Premium. Precision. Trusted.

TrakMotive® Automotive CV Axles transfer power from the transmission to the drive wheels of a vehicle. They consist of a CV Joint and Drive Shaft.

CV Axles are designed to work at varying angles, constant rotational speeds, without friction and play. CV Axles can be found in front wheel drive, four wheel drive and rear wheel drive vehicles, equipped with independent suspension systems.

OE Features & More

All Necessary Attached Hardware & Grease Included*

ABS-consolidated and assembled with correct ABS ring*

Premium Neoprene Dust Boots

Stainless Steel Clamps

Precision Machined Solid Steel Heat Treated Center Shafts

Precision Rolled Splines & Threads

Precision Machined & Heat-Treated Cages, Races & Bearings

High Strength Spring Steel Retaining Clips*

All New Dust Rings and Guards*

*where applicable

INDUSTRY LEADING COVERAGE

100% NEW MATERIALS

FIRST TO MARKET

EXTENDED SERVICE LIFE

EASE OF INSTALLATION

SALES & TECHNICAL SUPPORT

Updates

05/2024: TrakMotive Teams Up With Brenton Productions

TrakMotive Teams Up With Brenton Productions on MotorTrend TV TrakMotive is pleased to recommit as a participating sponsor of Brenton Productions for the 2024 season and will be featured in select episodes of Truck U and Two Guys Garage shows to better reach our...

06/2023: TrakMotive Don’t End Up Stranded with Inferior CV Axles

Don’t End Up Stranded with Inferior CV Axles TrakMotive® offers a true solution with the HD Xtreme™ CV Axle program, which is specifically designed to handle the most extreme environments.

05/2023: TrakMotive Maximize Your Subaru CV Axles Sales Opportunities

TrakMotive: Maximize Your Subaru CV Axle Sales Opportunities Addressing Subaru OE CV Axle binding issues.

04/2023: TrakMotive Maximize Your CV Axles Sales Opportunities

TrakMotive: Maximize Your CV Axle Sales Opportunities Featured HD Xtreme and Xtended Travel CV Axles.

03/2023: TrakMotive Teams Up With Brenton Productions

TrakMotive Teams Up With Brenton Productions on MotorTrend TV TrakMotive is pleased to recommit as a participating sponsor of Brenton Productions for the 2023-24 season and will be featured in select episodes of Truck U and All Girls Garage shows to better reach our...

01/2023: TrakMotive New Intermediate Shafts = Increased Sales Opportunities

New Intermediate Shafts = Increased Sales Opportunities TrakMotive® continues its commitment in providing leading market coverage to help maximize your sales opportunities. This includes our new Intermediate Shaft program that has been recently expanded to 51 SKUs,...

12/2021: TrakMotive Continues to Expand Leading Market Coverage

TrakMotive Continues to Expand Industry Leading “First to Market” Coverage As a recognized market leader in new CV Axles and Driveshafts, TrakMotive is clearly positioned as a leading resource for our customers in the automotive and power sports markets.

TrakMotive New HD Xtreme CV Axles Designed for Extreme Environmental Conditions

HD Xtreme CV Axles DESIGNED FOR EXTREME ENVIRONMENTAL CONDITIONS Extreme weather and rugged conditions can be tough on today’s vehicles. OE style CV axles function well in normal conditions but can be subject to premature failure due to extreme cold, heat and rugged...

TrakMotive New Xtended Travel CV Axles Designed Specifically for Lifted Applications

Xtended Travel™ CV Axles Designed Specifically for Lifted & Off-Road Applications What You Need to Know: A lifted vehicle dramatically increases the stresses of stock components and often exceeds the original design limitations. TrakMotive’s Xtended Travel™ CV...

05/2021: OE CV Axle Trends

What You Need to Know: Today’s vehicle drivetrain systems are far more powerful than ever before. So, you want to make sure the replacement CV Axle assembly matches the original OE design attributes to ensure quiet, dependable performance and durability.

Tech Tips

05/2020: TrakMotive Subaru HD CV Axles Solve OE Binding Issues

The Problem Developed from Original Equipment design. These CV axles rely on the inboard joint to provide all linear travel (plunge) for the CV axle. This limits the maximum angle this type of CV axle can operate at without binding to, 23° for a tripod style and 30°...

04/19: CV Axle Issues on Vehicles with Altered/Lifted Suspsensions

CV Axle Issues on Vehicles with Altered/Lifted Suspensions It has come to our attention that vehicles with altered (lifted) suspensions experience higher CV axle failure rates. This is because the high lift angle puts the wheel further away from the differential,...

02/2019: Practical Solutions to Common CV Axle Problems

Practical Solutions to Common CV Axle Problems OEM Axle Bearing BracketsProblem: Some OEM axle bearing brackets are prone to failure because they are made of low-density aluminum and prone to breakage when being pressed onto a new axle bearing. Solution: TrakMotive...

11/2018: TrakMotive Addressing Common CV Axle Issues

Removal & Installation Issues Removal Problem: Prying and striking the axle during removal often causes the circlip to become caught and damages both the axle and transmission splines. Solution: Use a CV removal tool that attaches to a slide hammer is the best...

11/2018: Addressing Subaru HD Axle OE Binding Issues

TrakMotive™ Subaru HD Axles Solve OE Binding Issues Problem: The original OE design relies on the inboard and outboard joint to provide all linear travel for the axle. However this axle design will often create a binding issue when installed on vehicles where the...

04/2018: A Visual Look At CV Axle Joints

A Visual Look At CV Axle Joints A New CV Axle is the Best Replacement Practice to Ensure Proper Fit & Long Lasting Performance CV joint housings are typically forged from iron billets. After the joint is machined, induction heat treating is used to harden wear...

2/2017: Tech Bulletin—Top 5 Noise Symptoms Associated With a Worn CV Shaft

1. Popping or clicking noises when turning. This indicates a worn or damaged outer CV joint. To verify this condition, place the vehicle in reverse, crank the steering wheel to one side and drive the vehicle backward in a circle (check the rearview mirror first!). If...

6/2016: Tech Bulletin—CV Axle Installation Tips

Tip #1 Prior to installation, make sure to physically match the replacement unit with the original unit. Sometimes replacement units may not appear the same as the original unit, but will function properly. Pay close attention to: a. Overall compressed length b. Inner...